Are you in the poultry business? Perhaps you are also producing a substantial number of eggs. If you are, you will need to find egg tray machine that you can use to produce cartons that will hold your eggs. You could work with a company that already has the equipment, purchasing everything that you need from these businesses. However, you may find it more economical to spend your money on machines of your own so that you can control the amount of money you are spending and how many you are able to produce. Want to find egg tray making machine price. Here are a few tips that you can use to get discounts on quality egg tray machines for your business if it is starting to generate more eggs than ever before.

How Do These Machines Work?

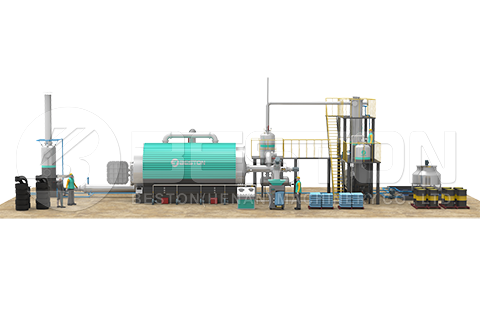

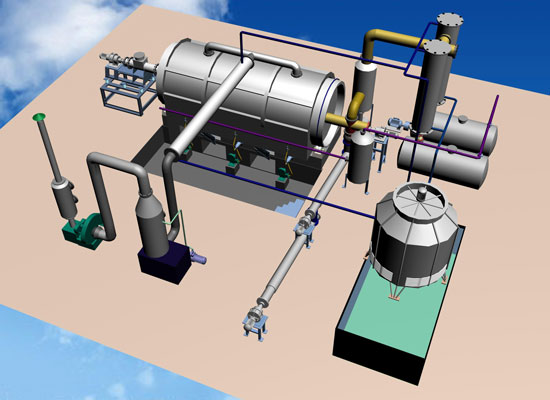

Despite the amounts of productivity that you will get out of these machines, they are relatively small. They will use a source of pulp that can be either from regular or recycled materials, pulp that is poured into the molds. These will then be heated until they have solidified in the proper form. From the forming system, the trays will be sent out on a conveyor belt. The more expensive models will also have complete drying systems, and stacking systems, so that you simply have to turn the machine on to how that produce. The reliable egg carton machine manufacturers can provide you high performance machine.

How Do You Find These Machines?

Quality egg tray machines can be found online after just a few minutes of searching. The main thing to consider is how much money you want to spend, and how automated you want the system to be. If you are a larger business that does not have the time to manually take the trays, or wait for them to dry in the sun, fully automated systems are the way to go. This will increase productivity for your business, and if it has been steadily growing, this can be a much needed asset to help your company generate more profits this year. Click here to know more: https://bestonpapermachine.com/.