If you’re working in a tight space, you’ll want to make the most of the room you do have. Instead of trying to fit a square peg into a round hole, you should try to find products that will work well for you.

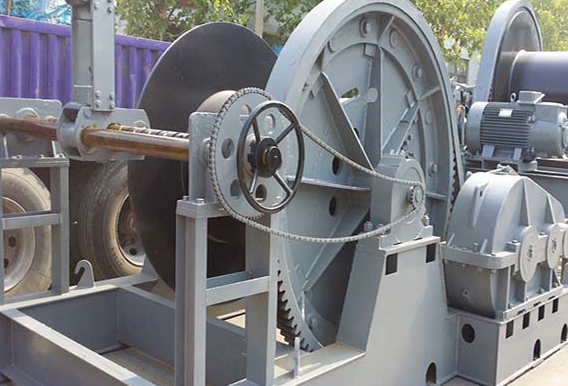

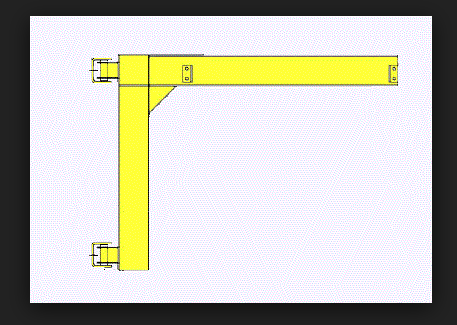

One thing you may want to look at is a low headroom electric hoist-space saving and high efficiceny. These hoists are designed with space efficiency in mind. A device like this will be able to save you a great deal of room.

Work Safely

Safety is always a concern in the workplace, but it can be especially important if you’re in a smaller space. A lot of industrial accidents occur because a piece of machinery came into contact with something else. When you’re in a small space, the risk of something like that occurring is much higher.

When you invest in popular low headroom electric hoist, you’ll have a lot more room to work with. Because of this, it will be easier for you to avoid accidents. You’ll be able to keep your workplace safe, day in and day out.

Work Efficiently

In many cases, limited space can reduce workplace efficiency. After all, when things are cramped, workers will have to work very slowly in order to carry out the job.

However, when you have extra room, your workers will have more space to work with. It will be easier for them to carry out their jobs correctly.

A tight space can reduce productivity, but the right products can bring it right back up again. Pick up a low headroom hoist, and you’ll be able to get a lot more done.

Work Affordably

Many people wrongfully assume that specialty hoists like this one cost a great deal of money. Thankfully, that isn’t actually the case. As a matter of fact, many products like this are comparable in price to many other electric hoists on the market, such as flexible travelling hoist, hoist with large loading ,

You don’t have to spend an arm and a leg in order to get a product that offers everything you need. If you take the time to price a few products, you’ll see how affordable a low headroom hoist can be.

Work The Right Way

At the end of the day, you need to invest in machinery that makes sense for your facility. When you’re able to free up some extra room, every aspect of your job will be easier.

There’s no reason not to invest in the right kind of hoist. Don’t bother with hoists that require a lot of space; look for something that will be able to save you some room. You’ll be happy that you paid for a product like this one.

There are products out there that are well-suited to every work space. If you’re not happy with the hoist you currently have, look into upgrading to a low headroom hoist. With the right hoist, you should be able to accomplish a lot with a little. These hoists can save you a lot of space.

Throughout the years,

Throughout the years,