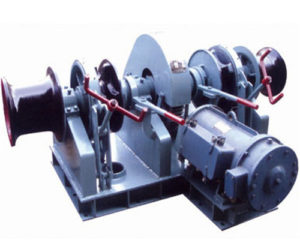

Have you been trying to find an electric hoist winch for sale which you can use at your facility? You may want one that will lift up to 20 tons, or perhaps over 100 tons, and these are common definitely available. Your decision will depend upon how much cash that it will surely cost in choosing in the many companies that sell them. Additionally you choose them based upon their capabilities, wire rope capacity, loading capacity, and the speed from which they operate. Other considerations include safety measures that let them decrease and do emergency stops. Now let’s check out the manner in which these actually work so that you can understand how complex these single drum winch machines for sale from Elllsen supplier actually are, then where for the greatest ones.

How Does A Winch Hoist Actually Work?

To begin with, there exists some variation from the words winch and hoist that need to be discussed. The real difference is the fact that a hoist is what you will use while you are lifting things up, as well as a winch is made to pull things. For example, an electric hoist winch for sale in Ellsen factory is made with gears that can pull things over level surfaces. They have dynamic brakes, ones that must definitely be capable to slide, and in addition do emergency stops. A hoist, on the other hand, is about lifting deadweight. It will furthermore have a locking brake because you will have to stop the burden and possess it hanging while you are doing any sort of lifting. Therefore, the mechanisms must be a little different based on the type of weight they are pulling, simply how much weight, and also the direction in which these well build and popular single drum winch for sale products has been lifted or pulled. These changes pertain to the gears that happen to be inside, as well as the mechanisms that allow it to function. Also, they are designed to do business with various kinds of materials like cables, ropes and chains, all of which will ultimately result in the final product that you are likely to buy.

Ellsen offers many kinds of electric hoist winch for sale, with high quality and low price, as well as lifetime maintenance, if you want to know more,you can click here www.ellsenwinchsales.com/hoist-winch-sale

Obtaining One That’s Good For You

Based upon this information, you can see that you should get one based on what you will do probably the most of. If you are going to get pulling such things as pulling load behind a boat, mooring on the dock, then a high quality and low price electric hoist winch for sale is what you should need. If you are going being lifting things coming from a gantry crane since you are loading and unloading containers from ships, then the hoist will probably be necessary. There are certainly the ones that can do both, and you need to take into account that if you are making your final decision.

Buying One From Your Right Company

If there is one company that stands apart amidst every one of the others it is actually a business called Ellsen that creates an unbelievable amount of cable winch products for sale. They are industry leaders in producing hoists that may be purchased on all their websites. They are able to lift and pull loads that exceed 100 tons easily, and are generally all made with safety in your mind. In case you have not found one that is what you are looking for, you should certainly consider going to their site and requesting info on the many high speed winch for sale they have available.