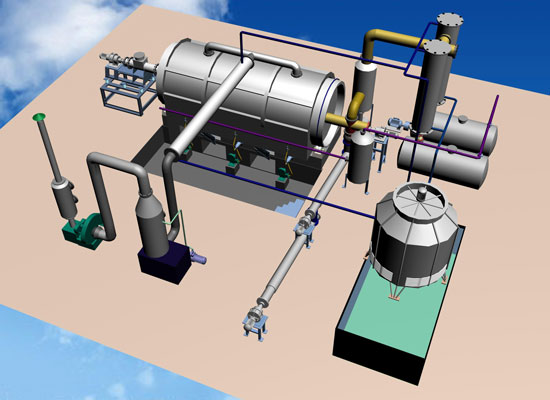

The manufacturer of pyrolysis equipment presents several pyrolysis machines for processing products like pyrolysis liquid fuel and carbon. These products are eventually converted to commercial fractions. This pyrolysis equipment is a tad more relevant for the plastics good and mechanical rubber goods utilization fields because not only does the utilization stay strong, but also because the utilization helps in converting plastics, mechanical rubber items, waste oil and oil sludge into highly marketable products like soot, diesel and activated carbon. A plant dealing with the manufacture and utilization of small pyrolysis machine ensures every new set of the pyrolysis machine by regular and consistent analysis of data, proper feedback and by consulting with the partners who operate this equipment.

The small scale plastic pyrolysis machines usually belong to the group of the operating plant. However, it is still easier to feed materials and process about 6-8 tons of waste plastic on a daily basis. On top of this, the plastic recycling plant also takes up lesser space, thereby turning out to be tad more useful. This plastic recycling machine effectively converts waste plastic, waste tyre, waste rubber and medical waste into proper fuel oil. The equipment is structured with an unique technology for increasing the oil output and reducing the fuel consumption which further brings more benefits for you. Get the a quality waste tyre to oil plant from reliable manufacturer online.

Why Should You Go For The Small Pyrolysis Plant?

These equipments are widely popular as they come equipped with a series of safety devices including an alarm for controlling the temperature, a pressure releasing system that works automatically, high end systems that are used in de-dusting water spray, washing chambers and ceramic ring filters. These systems also guarantee an effectively safe, energy conserving and environment friendly waste plastic pyrolysis process.

Security Design Of Small Scale Plastic Recycling Equipment

The security of the major device includes those specific exhaust gas components that cannot be liquefied. Therefore, they are first made to pass the water seal before being burned as fuels. Right after that, they are made to pass the gas burner of the subsequent safety equipment.

The hydroseal is used to stop the fire to burn back while it effectively removes sulphur and impurities while cleaning the desulfurization gas.

The auto welding machines of these, equipment not only bucks up the efficiency and further guarantees the quality of welding.

There is a specific operating tech that deals with every possible bug during the production process.

The small scale plastic pyrolysis machines come with a proper pressure gauge and thermometer gauge which is used for inspecting the pressure and temperature at any and every possible time.

Comes with a 100% technology for avoiding burns.

Equipped with a technology that protects it from explosions.

During daily operations the room for exhaust gas is closed. However, when the pressure is uncontrollably high this room can be opened; the combusted gas can be directly burned and can be further used to lower down the temperature and the air pressure from the reactor. Continue reading here: waste to energy projects.

Prevents every possible technique for the outlet clogging of valves.