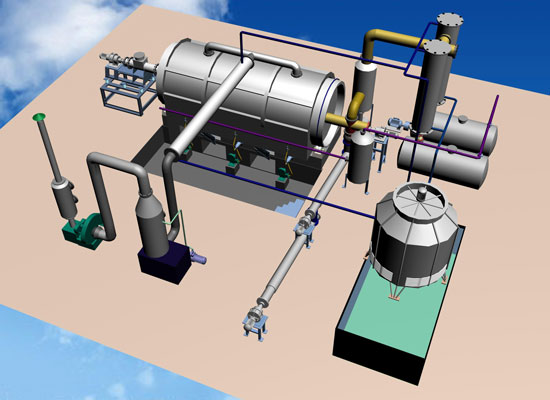

The plant has become something you need to look at as a person who wants to pursue the right options. You don’t want the construction project that is unfolding in front of you to become a real issue. This happens when people are not able to think about what should be done next.

The best solution is always the one that makes things better for you in the short and long-run. Which option would that be when it comes to mortar? You will want to go with the high-quality dry mortar production line as the solution that will provide results.

Here is more on it.

1) Precisely Mixed

The dry mix has to be precise because you are not going to be able to do the work that needs to be completed without it. The dry mix has to be consistent and up to par with the standards you are setting in the industry. You cannot use a mix that is not precise because it won’t be meeting what you are looking to uphold.

There are things where you are not going to approve the idea of cutting corners and the mix you are using would be one of them without a doubt.

You can’t let this get to a point where you are not sure about the mix.

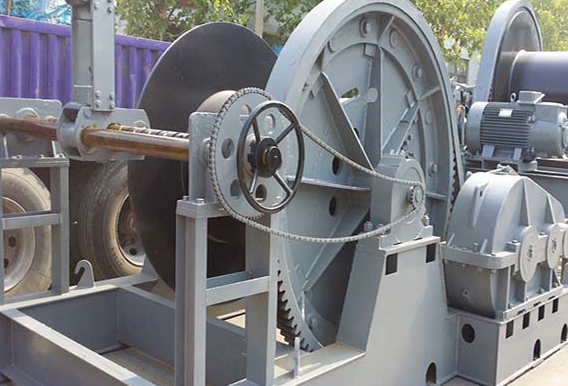

2) Streamlined

If things become wonky, you are the one who is going to pay for it. You can’t have a situation where you are sitting by the plant praying that it does not cause issues and is reliable with the output. It should be a streamlined process where you are aware of how much you are going to get and when you are going to receive it from the machine.

Anything less and you should not be using that machine at all.

You want to get this dry mix mortar plant to do the work in an orderly manner.

3) Clean

You don’t want a mess to be made by the plant you have selected. This happens with older options where the machine does create enough output for you to smile, but also leads a disastrous trail that is not good enough. You have to think about all of these details as you hope to maximize the value being brought forward.

You want to look at everything in the long-term because those who are reckless will ruin their construction site.

You want to make sure it is as clean as you need it to be.

Those who are not able to get the right dry mix mortar plant or dry mortar mixer will be the ones who are going to despise what they are doing onsite. You are going to get to work and realize that the plant is not working the way it should. You never want that to happen.

This is why people put money into this plant because it is known for doing a good job and is going to provide that clean, sustainable dry mix that you are going for. Most people need that for their projects. For more information about this machine, you can visit this website: http://www.zzchangli.com/.

Throughout the years,

Throughout the years,