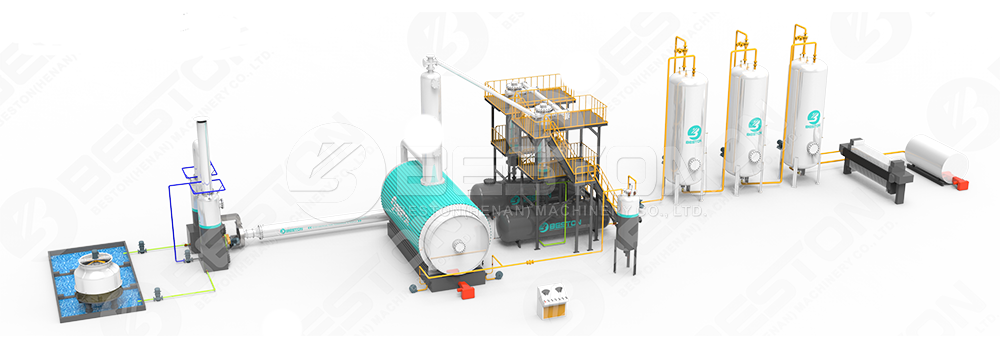

The pyrolysis unit is widely used in many countries since it doesn’t cause any kind of pollution. This plant conducts a process which is called as pyrolysis in which the whole of the plastic scraps are treated at an elevated temperature. This process is conducted in a closed container without the presence of oxygen.

Plastic waste is thought to be most harmful for mankind. The pyrolysis consultant granulates these plastics without oxygen and produces an immaculate quality completed product called pyrolysis oil. This waste pyrolysis plant requires just plastic waste or tire wastes as the crude material. Each plastic to oil machine utilizes green innovation as a part of request to convey forward the procedures in an ecological agreeable way.

Advanced pyrolysis technology enables safety along with flexibility in operation and profitability. Energy derived from the recycling of plastic is used for the operations of the plastic pyrolysis machine and hence it can be considered as energy self-sufficient. External fuel is not used for heating purposes as well. The quality of the oil obtained from the plastic pyrolysis process can be improved with the latest waste oil distillation plant.

Industrial and household plastic wastes can be passed through the pyrolysis of waste plastic plant for recycling, which can be considered as a major advantage of the pyrolysis process. Plastic mixtures of Poly-Propylene, Poly-Ethylene and Poly-Styrene can be recycled through this process. Another highlighted feature of plastic pyrolysis machine is its low maintenance and running cost. The concept behind the pyrolysis process can be said to be revolutionary in the sense that it is completely environmental friendly. No pollutants are generated from pyrolysis of waste plastic as the entire process is carried out in a closed environment.

Global level focus and consideration are required for plastic recycling through pyrolysis as this process has the ability to convert a huge amount of plastic waste in the most efficient and effective manner. A positive approach towards this process ensures the recovery of valuable natural products. Both environmental and social benefits can be achieved from this process. With flexible utilization of the pyrolysis process, fast disposal and recycling of plastic waste without the emission of ash,which is a potent compound, are possible.

It also always recommended to lesser down the use of polythene due to the fact that it takes thousand of years to decompose small fraction of it. But, in waste plastic pyrolysis plant the plastic products can be decomposed very quickly that too without polluting air or underground water. This plant is really useful in all aspects and must be installed in an industry if you want to live in safe and pollution free environment.